How do we make our dishes?

-

Selection and control

Our experts select the best raw materials in the market and our suppliers and their produce are subject to strict quality controls.

-

Safe production

We have independent production rooms to guarantee quality and safety.

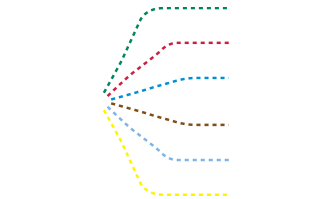

to prevent cross-contamination, we have:

A vegetable handling room, where all the elements used are green.

A meat handling room, where all the elements used are red.

A fish handling room, where all the elements used are blue.

In the hot kitchen all the elements used are black.

In the cold kitchen all the elements used are white.

And we have a specific kitchen for gluten-free products where all the elements used are yellow, as required by the HACCP. -

Disinfection of containers

In our decontamination rooms we use chlorinated water to disinfect all the containers used to deliver the raw material. Decontamination is enormously important for avoiding cross-contamination and ensuring that the product is safe and keeps all its original properties intact.

-

100% natural recipes

Our expert chefs prepare a wide variety of delicious and healthy recipes. The dishes are made the traditional way but with shorter cooking times to ensure that the food retains the maximum level of nutrients, flavour, colour and texture.

We therefore obtain a dish that is 100% natural, using nothing but olive oil.

Products for coeliacs

We have a separate kitchen where we prepare recipes suitable for coeliacs.

Vacuum packing

Once the dish has been pre-cooked, we wrap it in a heat-sealed tray with a protective atmosphere: vacuum heat-sealed up to 99% and the remaining 1% CO2+N.

Thanks to this process we can create a safe product from the health and hygiene point of view, with a very high percentage of 99%. A product of the highest quality in terms of taste, colour, texture and nutritional value.

Key heat treatment

We product then undergoes heat treatment, a key process in extending its life and keeping all its properties intact.

The heat treatment consists of 3 phases: pasteurisation, chilling and regeneration.The first two phases are applied immediately after packaging the product with a protective atmosphere.

The third, regeneration, is carried out by the customer and involves heating the container in the microwave for 3 minutes before eating.

For a pre-cooked meal to be considered 5th Range, the total preparation time must take no longer than 120 minutes, including packaging, pasteurisation and chilling. At Bost Gourmet we complete this process in less than 120 minutes to guarantee that the product retains its full nutritional, organoleptic and hygienic properties.

Product refrigeration

We keep the product refrigerated at between 0º and 4ºC during its transfer from our kitchen to our customers' facilities, always maintaining the cold chain. And to do it, we have especially refrigerated transport.

Heat and serve

Our dishes are simple, fast and easy to regenerate. Simply heat them in the microwave, frying pan or oven for a few minutes.

At any time of day, with nothing but a microwave and with no need for a chef, you too can enjoy a high quality dish as if it were freshly made.

-

1

Selection and control

Our experts select the best raw materials in the market and our suppliers and their produce are subject to strict quality controls.

-

2

Safe production

We have independent production rooms to guarantee quality and safety.

to prevent cross-contamination, we have:

A vegetable handling room, where all the elements used are green.

A meat handling room, where all the elements used are red.

A fish handling room, where all the elements used are blue.

In the hot kitchen all the elements used are black.

In the cold kitchen all the elements used are white.

And we have a specific kitchen for gluten-free products where all the elements used are yellow, as required by the HACCP. -

3

Disinfection of containers

In our decontamination rooms we use chlorinated water to disinfect all the containers used to deliver the raw material. Decontamination is enormously important for avoiding cross-contamination and ensuring that the product is safe and keeps all its original properties intact.

-

4

100% natural recipes

Our expert chefs prepare a wide variety of delicious and healthy recipes. The dishes are made the traditional way but with shorter cooking times to ensure that the food retains the maximum level of nutrients, flavour, colour and texture.

We therefore obtain a dish that is 100% natural, using nothing but olive oil.

5

Products for coeliacs

We have a separate kitchen where we prepare recipes suitable for coeliacs.

6

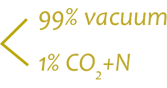

Vacuum packing

Once the dish has been pre-cooked, we wrap it in a heat-sealed tray with a protective atmosphere: vacuum heat-sealed up to 99% and the remaining 1% CO2+N.

Thanks to this process we can create a safe product from the health and hygiene point of view, with a very high percentage of 99%. A product of the highest quality in terms of taste, colour, texture and nutritional value.

7

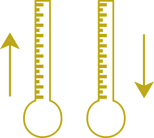

Key heat treatment

We product then undergoes heat treatment, a key process in extending its life and keeping all its properties intact.

The heat treatment consists of 3 phases: pasteurisation, chilling and regeneration.The first two phases are applied immediately after packaging the product with a protective atmosphere.

The third, regeneration, is carried out by the customer and involves heating the container in the microwave for 3 minutes before eating.

For a pre-cooked meal to be considered 5th Range, the total preparation time must take no longer than 120 minutes, including packaging, pasteurisation and chilling. At Bost Gourmet we complete this process in less than 120 minutes to guarantee that the product retains its full nutritional, organoleptic and hygienic properties.

8

Product refrigeration

We keep the product refrigerated at between 0º and 4ºC during its transfer from our kitchen to our customers' facilities, always maintaining the cold chain. And to do it, we have especially refrigerated transport.

9

Heat and serve

Our dishes are simple, fast and easy to regenerate. Simply heat them in the microwave, frying pan or oven for a few minutes.

At any time of day, with nothing but a microwave and with no need for a chef, you too can enjoy a high quality dish as if it were freshly made.